RSAE Labs Inc. has been focused on a application that hasn’t received the attention that other applications like Smartgrid, building/residential automation, and industrial automation have received. RSAE Labs Inc. has focused on the critical logistics monitoring market of position, status, and security to provide logistics intelligence, intrusion detection, and situational awareness. This focus is unique in that it also required the development of hardened global tracking devices, redundant global communications, along with a network capable of very high node densities and very high-count hop paths.

The mist® mesh network is based on the 2.4 GHz band physical layer of IEEE Std 802.15.4. IEEE 802.15.4 devices are among the most popular and capable devices being used in M2M networks including Thread, ZigBee, WiSUN, WirelessHART, ISA100.11a, and many proprietary networks.

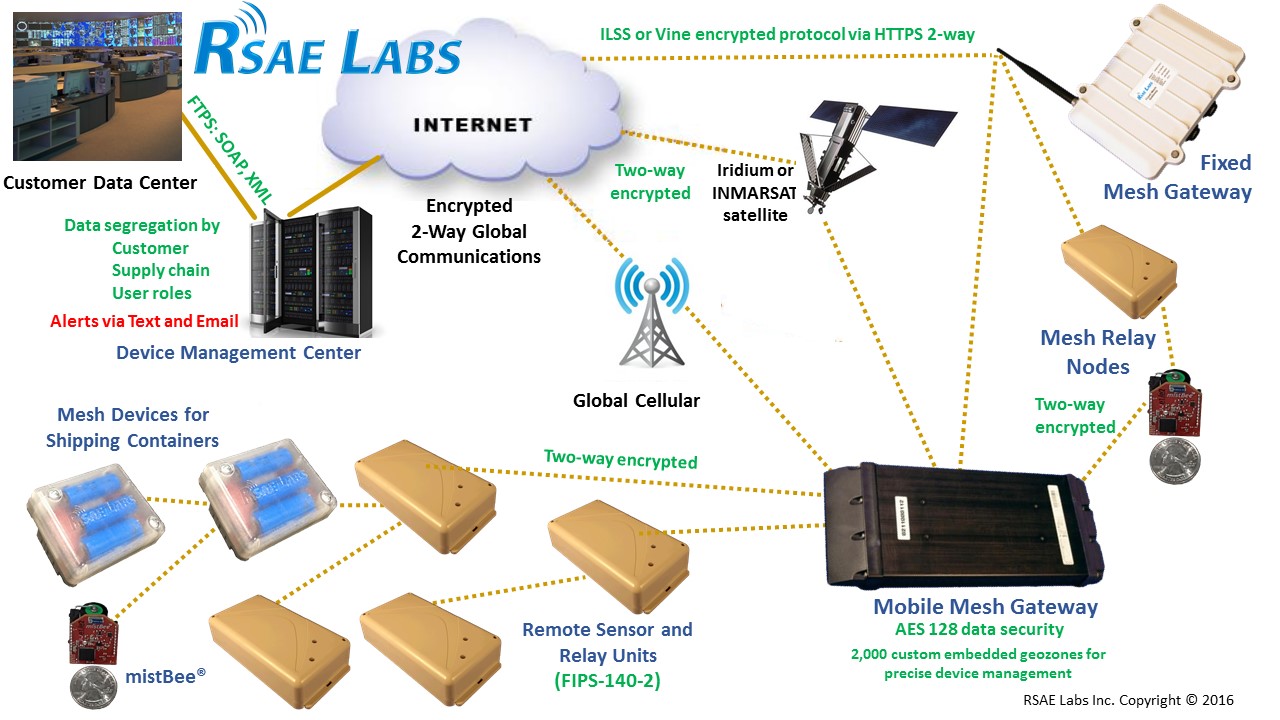

Caption: mist® Syetm Architecture

The mist® network is time scheduled channel hopping (TSCH) with similarities to prevalent networks used in industrial automation that are based upon IEEE Std 802.15.4, i.e. WirelessHART and ISA100.11a, and also to an IEEE/IETF development effort named 6tisch. Communication links between nodes are timeslot based on a schedule that is known to both nodes.

One significant difference to industrial automation wireless mesh networks is that the mist® network is ad-hoc, while the industrial automation meshes are network managed.

Even though mist® is an ad hoc mesh network, each device is rigid in its relationships to its neighbors, there is one default parent with one backup parent and up to four children. This design creates a natural hierarchical network that requires minimal maintenance and simpler routing schemes compared to current CSMA networks using AODV routing. Routing times between peer to peer nodes in hierarchical networks are slower than networks using AODV routing but for many applications such as logistics the time difference is inconsequential since the data flow for each node is dominated by the flow either to or from a single node such as a gateway.

Another difference between mist® and industrial automation mesh networks is that the typical hop length for many mist® installations is 20 – 30 hops while industrial automation hop lengths typically range up to 5 hops, with 9 hop lengths being the maximum. A recent mesh routing method comparison whitepaper by Owczarek and Zwierzykowski concluded that a typical wireless ad-hoc mesh using AODV routing can handle up to 20 mobile nodes before it gets saturated, while mist® hierarchical mesh networks often handle 1000’s or more nodes.

Most mesh networks allow any device to initiate a communications exchange, but the mist® protocol only allows an authorized server device to initiate communications. Thus a parent must send an authentication packet to a child to allow that child to send an information packet to that parent.

Finally, the mist® network devices have ruggedized temperature ranges with higher levels of security than the industrial, commercial, and residential network devices.